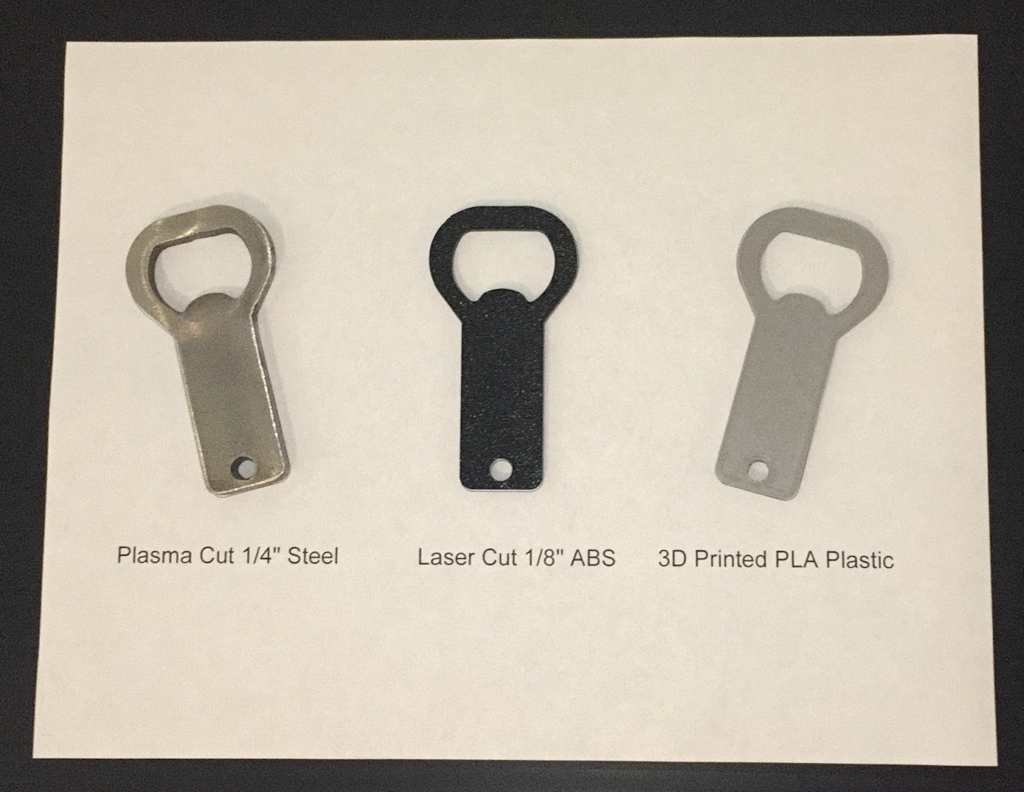

3D Printing opens the door to allow the testing of a concept design or prototype, without committing to a large quantity and the upfront cost of die, laser, or plasma cutting. Before you put your item into production, consider whether or not the design is finalized. If it is not, 3D printing may be the right choice for you. We will take your design or CAD file, and print it out in one of the available colors we have. Our current color options are black and grey, but other colors are available upon customer request. Our 3D printing size constraints are: 220mm x 220mm x 250mm or 8.5″ x 8.5″ x 9.5″

High accuracy and precision can be achieved through the printing process, usually to around +/- 0.1mm, and in some cases +/- 0.05mm can be accomplished. 3D printing is the most cost effective way to get a concept or prototype part completed in low quantities, and allows for multiple iterations of a part within a single order. All of our other processes (die, laser, plasma) require some amount of setup and upfront material cost, which is not the case with 3D printing.

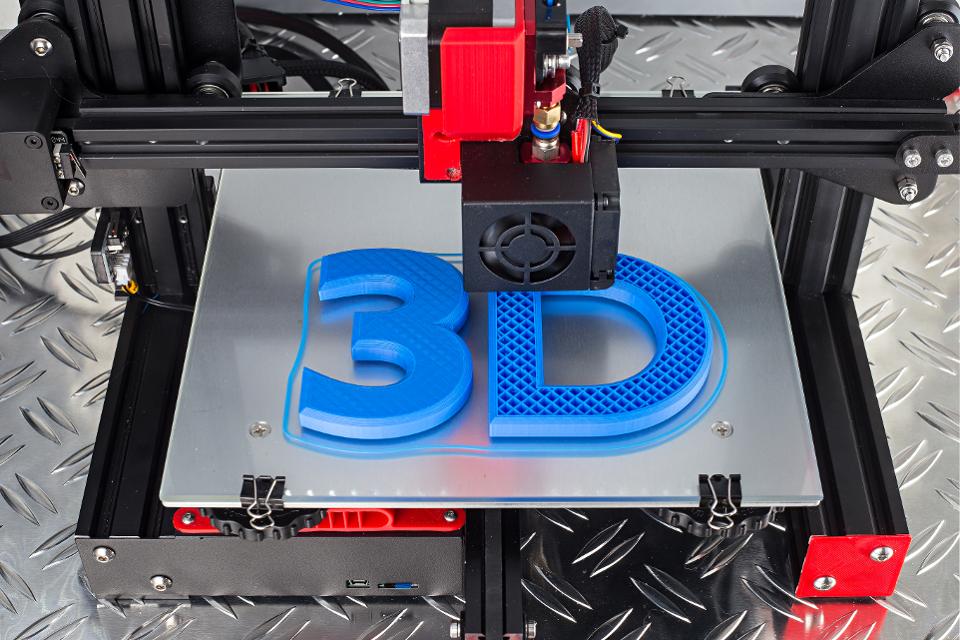

For a short demo, check out our 1 minute video on Rapid Prototyping