Mag-Knight Die Cutting Services: Looking for custom parts? As previously mentioned, we can make your custom product from a number of materials including foam, sheet plastic, corrugated plastic, composite, fiberglass, chipboard, rubber, fabric, felt, cork, wood, flexible magnets, sponge, masonite, alumina felt, thin soft metals or any other flat material typically found in the industry.

Die Cutting Products Capabilities: We use platen presses for all of our processes. A platen press is essentially two parallel plates that press the material between a cutting board surface and a steel rule die to punch out the parts. Platen presses have the greatest accuracy and produce parts quicker than most other conventional methods for the above materials. Our presses can produce over 88 tons of pressure with a maximum platen size of 35″ x 60″.

Accuracy: Typically we fabricate parts to a nominal tolerance of +/-.015″. If you require tighter tolerances than this please let us know and we will do our best to suit your needs.

Die Cutting Services Environment: All of the products we die cut require us to have a very clean environment. Since many are consumer products, we must be very careful to ensure that they maintain their perfect appearance. This same careful attention to detail will apply to your job as well.

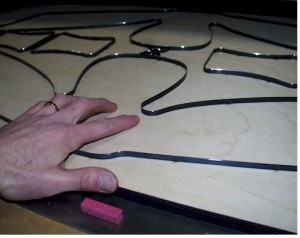

Tooling: In order to produce your parts, your custom order will require a steel rule die. A Steel Rule Die is essentially a cookie cutter from which we stamp your parts from. Parts can vary in size and shape and a SRD is the least expensive option for making thousands of parts from these materials.

Turn Around: Upon approval of your design, we typically have your parts ready to ship in less than two weeks. That is unheard of in the industry to go from concept to reality in less than 2 weeks time. We utilize the very latest in CAD software and exacting methods to reduce wasted time. You get your parts faster and on budget…every time!