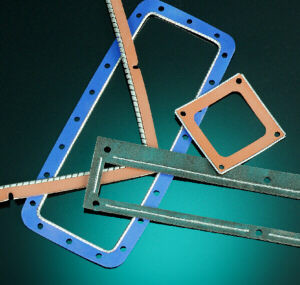

Custom Die Cutting Products & Services

We offer high quality, low cost nationwide die cutting products & services for any sized firm. From one man businesses to large manufacturers like Boeing, General Dynamics and Freight-liner Trucks; we service all companies equally. We have the ability to take your project from concept to reality in less than 2 weeks using the latest CAD technology and manufacturing techniques. Your account will be personally reviewed and handled by a Mechanical Engineer to ensure the highest quality parts are made at the lowest possible cost. In fact, our prices are considered to be the lowest in the industry while our expertise is among the highest.

Custom Die Cutting Services Materials:

We routinely fabricate custom gaskets, foam, sheet plastic, corrugated plastic, composite, fiberglass, chipboard, rubber, fabric, felt, cork, wood, flexible magnets, sponge, Masonite, alumina felt, and thin soft metals. Please visit our materials section for a comprehensive list of materials. This section will also give detailed information regarding which materials are best suited for laser services or steel rule processes.

Company Background: We have been in the business for over 25 years. We pride ourselves in providing excellent customer service at rock bottom pricing.

How can we do this? Well, we own (not lease) all of our equipment, buildings and offices. This enables us to surpass our competitor’s bids because they have to factor in at least 25% additional margin to pay for these. In fact, our hourly press time is only $100 while our closes competitor estimates their jobs at $150 per hour. For proof of this, visit the pricing section of the website. It gives an account of an actual part we still manufacture and how our firm’s prices stacked up against our competition. On top of this, where else can you find a Mechanical Engineer on staff to help you design your parts? Our company president has a Mechanical Engineering Degree from Michigan State University with over 10 years aerospace design and manufacturing experience at The Boeing Company.

Clean Environment: All of the products we manufacture require us to have a very clean environment. Since many are consumer products, we must be very careful to ensure they maintain their perfect appearance. This same careful attention to detail will apply to your job as well… large or small. Take a look at how clean our press is in the sidebar videos.

Tooling: In order to produce your parts, your custom order will require a steel rule die. a Steel Rule Die (SRD) is essentially a cookie cutter from which we stamp your parts from. Parts can vary in size and shape and a SRD is the least expensive option for making thousands of parts from. Please review the Steel Rule Die Tooling section of this site for more information.

Minimums: We do not have a set minimum on any job. However, runs under 500 units tend to be expensive per part when you amortize tooling costs and cutting service into the equation. Our average tooling cost is $250. For a custom quote on your next job see our Quotation page.

Payment Information:

Accepted

Accepted

Contact Us:

Phone: 360-805-0100 Fax: 360-805-0811 Email us